At the very earliest stages of the introduction of the laser cutter, the asset was only reserved for niche developers. Whether they were based in manufacturing, retail, IT or the arts, this is not exactly a commonplace purchase to make. Thankfully the expansion of access to technology and speed of innovation has broken down those barriers. We will look at the selling points that make these designs more popular and more accessible, regardless of their specific application.

Very Affordable

One of the key features that makes the modern laser cutter a common purchase is that the design is within the reach of most participants. From businesses to sole contractors and DIY artists, these utilities can be sourced at affordable rates with rental opportunities also on the menu. This is ideal for people who want to achieve quality outcomes with their projects but cannot justify a major expense. By scouting the market extensively, it will be possible to gauge where the best price fit happens to be found.

Works Across Different Material Types

What has delivered better results for members that use a laser cutter is the capacity to engage different material formats. No longer are constituents restricted by what they can cut and manipulate before needing to use other utilities. From woods to plastic, ceramic to glass, stone to stainless steel and aluminum to tile, these assets can cover the full spectrum. That degree of versatility is a major selling point for any practitioner who wants genuine value for their money.

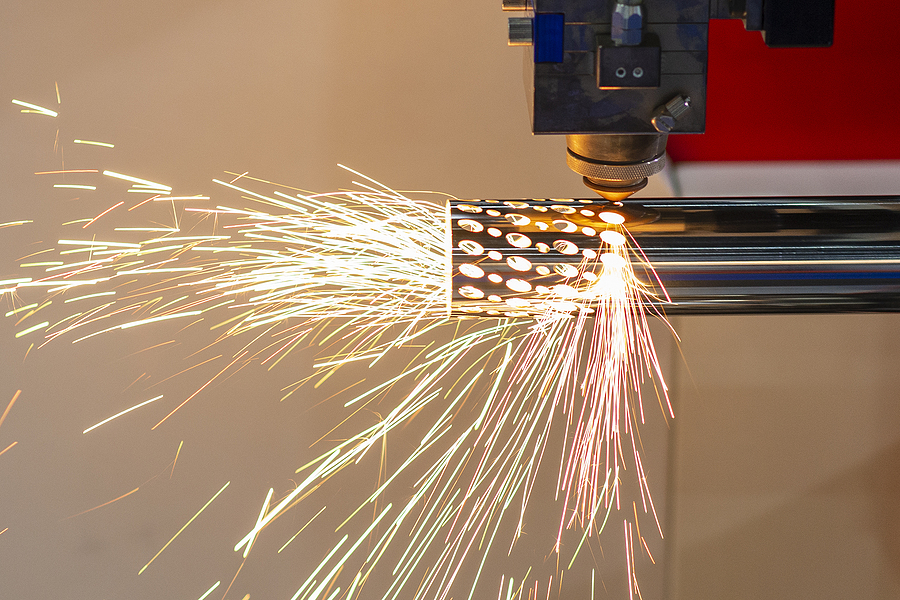

Safety Guaranteed

Technical operators who are taking a closer look at these laser designs will notice that zero touch is required. There will be no instance where contact has to be made. This greatly reduces the chance of suffering an injury and experiencing the kind of permanent harm that is not worth contemplating. For any workspace that needs to adhere to strict occupational health and safety standards, this is an investment that ticks all of the relevant boxes.

Digital Integration & Project Versatility

The joy of having a zero touch operation through the modern laser cutter is that specialists can work, cut and manipulate these materials with the very best of digital software integration. Even if the task appears too intricate and complex, these systems offer a tangible solution and methods that were not possible in years gone by. This is a way of opening up more potential, extending the reach of designers and ensuring that they are commercially competitive in spite of the competition.

Outstanding Cutting Precision

The introduction of a laser cutter will ensure a margin of error of 0.0005 inches. Such is the minutiae of this size, it won’t be evident to the naked eye or even a microscope. It is the ideal solution for specialists that want to reduce cases of human error, to boost productivity and keep pace with other brands and contractors who live and die by their accuracy to cut well.

First-Class Customer Service

In the event that the user is a bit lost or confused about the laser cutter as a modern application, then they should have sufficient customer service to lean on. From representatives who are happy to offer their insights with video tutorials, online messaging and phone calls, no one will be left to their own devices on this front. It is ideal to identify a brand that caters to this requirement through an official service agreement.

Any practitioners who are eager to pursue their very own laser cutter will be able to examine the 5-star ratings system and comments that consumers provide for each supplier. Speak to experienced clients in the know and see how they operate in real time before reaching a conclusion on the topic.